- About

- ARISTECH Location

- Phone : 886-4-2491-9588

.jpg)

| ITEM | LT45 | |

|

Work-Tank size (W × D) |

mm |

1100×670 |

|

Work table size (X × Y) |

mm |

800×550 |

|

Work table travel (X×Y) |

mm |

500×400 |

|

Max. cutting thickness |

mm |

300 |

|

Max. work-piece size (W×D×H) |

mm |

500×400×300 |

|

Max. work-piece weight |

kgs |

400 |

|

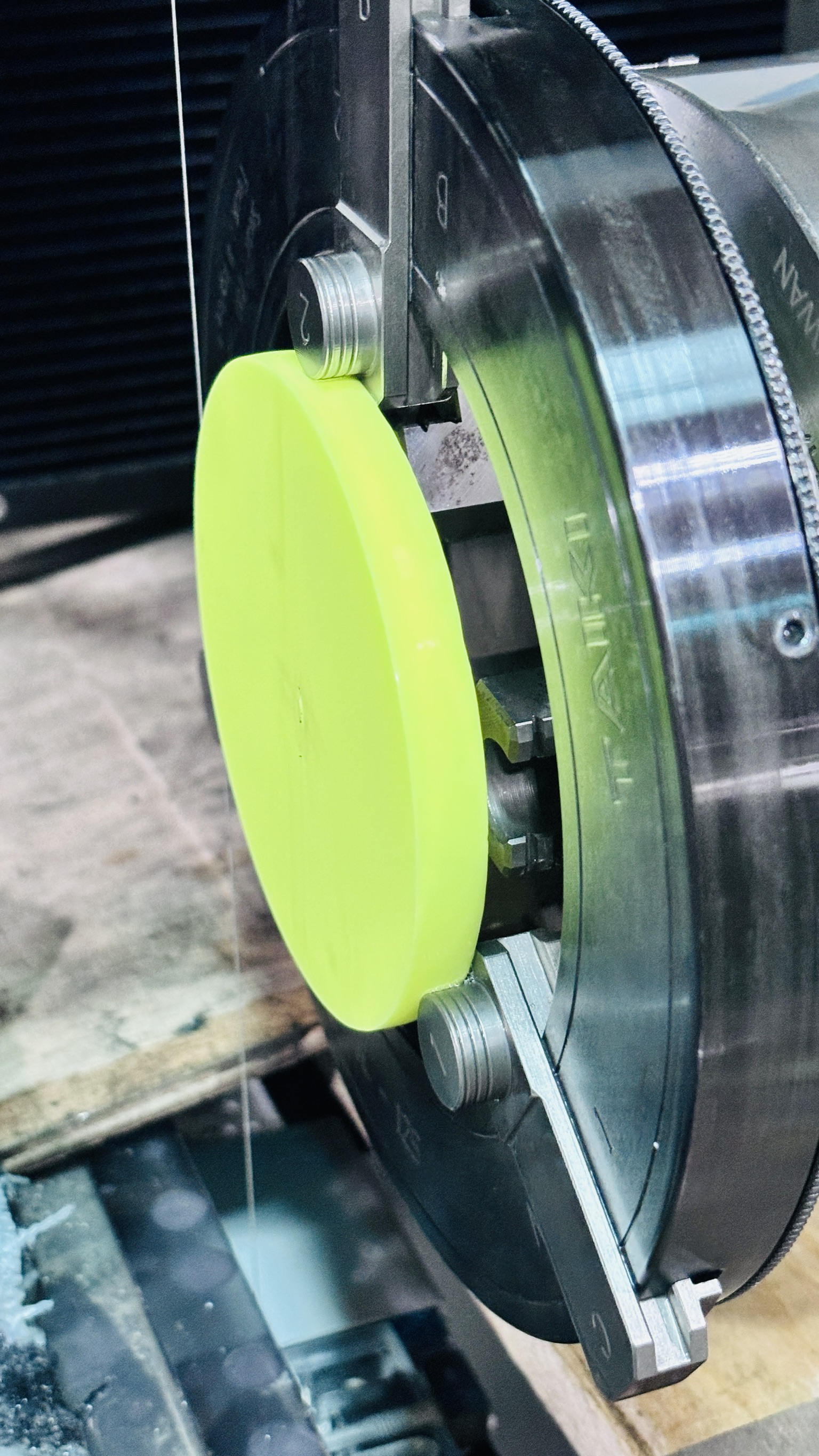

Dia. of abrasive wire |

mm |

Ø0.33(Standard) |

|

External dimensions (W×D×H) |

mm |

1950×1470×2000 |

|

Packing dimensions (W×D×H) |

mm |

2000×1710×2245 |

|

Packing dimensions (W×D×H) |

kgs |

1850 |

| ※Specifications subject to change without notice. | ||

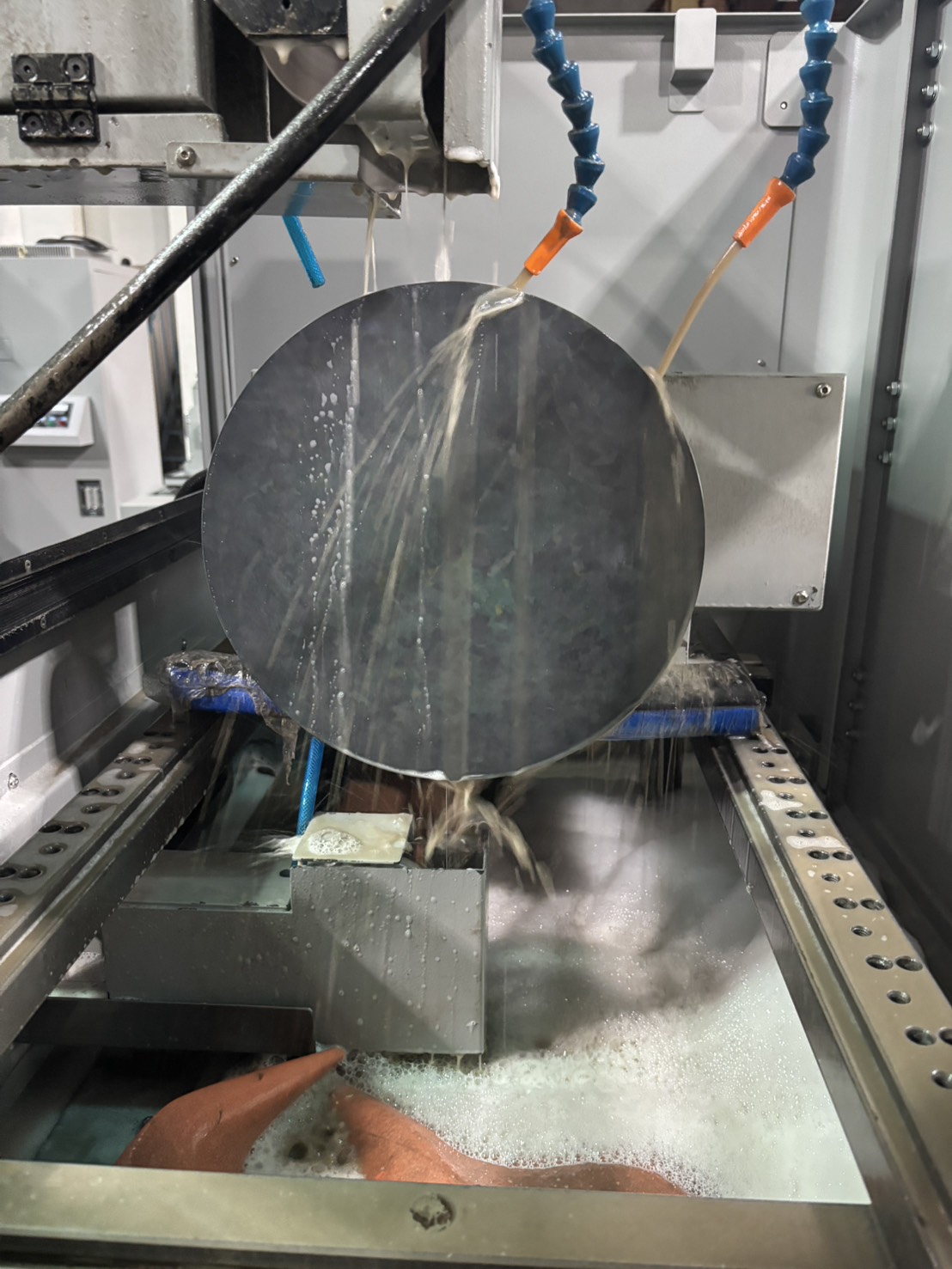

| DIELECTRIC FLUID UNIT | ||

| Capacity of dielectric fluid | L | 120 |

| Dielectric fluid tank size (W×D×H) |

mm | 900×500×280 |

| POWER SUPPLY UNIT | ||

| Cutting accuracy | mm | 0.08 |

| Best finish roughness | µmRa | 1.0(Optical glass material) |

| Max. power consumption | KVA | 3.0 |

| External dimensions (W×D×H) | mm | 900×610×1700 |

| Packing dimensions (W×D×H) | mm | 900×780×2000 |

| Net weight | kgs | 200 |

| ※Specifications subject to change without notice. | ||

| 1. | Program editing |

| 2. | (a) On-line edit (simple CAD) (b) N.C. code edit (G.M code) (c) 3B code edit (d) DXF edit (CAM, graphic transfer file) |

| 3. | Forward or reverse orbital function |

| 4. | Automatic or block stop machining |

| 5. | Mirror image function |

| 6. | Coordinate rotation function |

| 7. | Dry run function |

| 8. | Battery backup for memory |

| 9. | (MDI) manual data input |

| 10. | Start point or hold point return |

| 11. | Wire diameter compensation |

| 12. | Cutting path compensation |

| 13. | Cutting path display |

| 1. | USB,LAN Port. | 1 set |

|---|---|---|

| 2. | Magnetic work lamp | 1 pc |

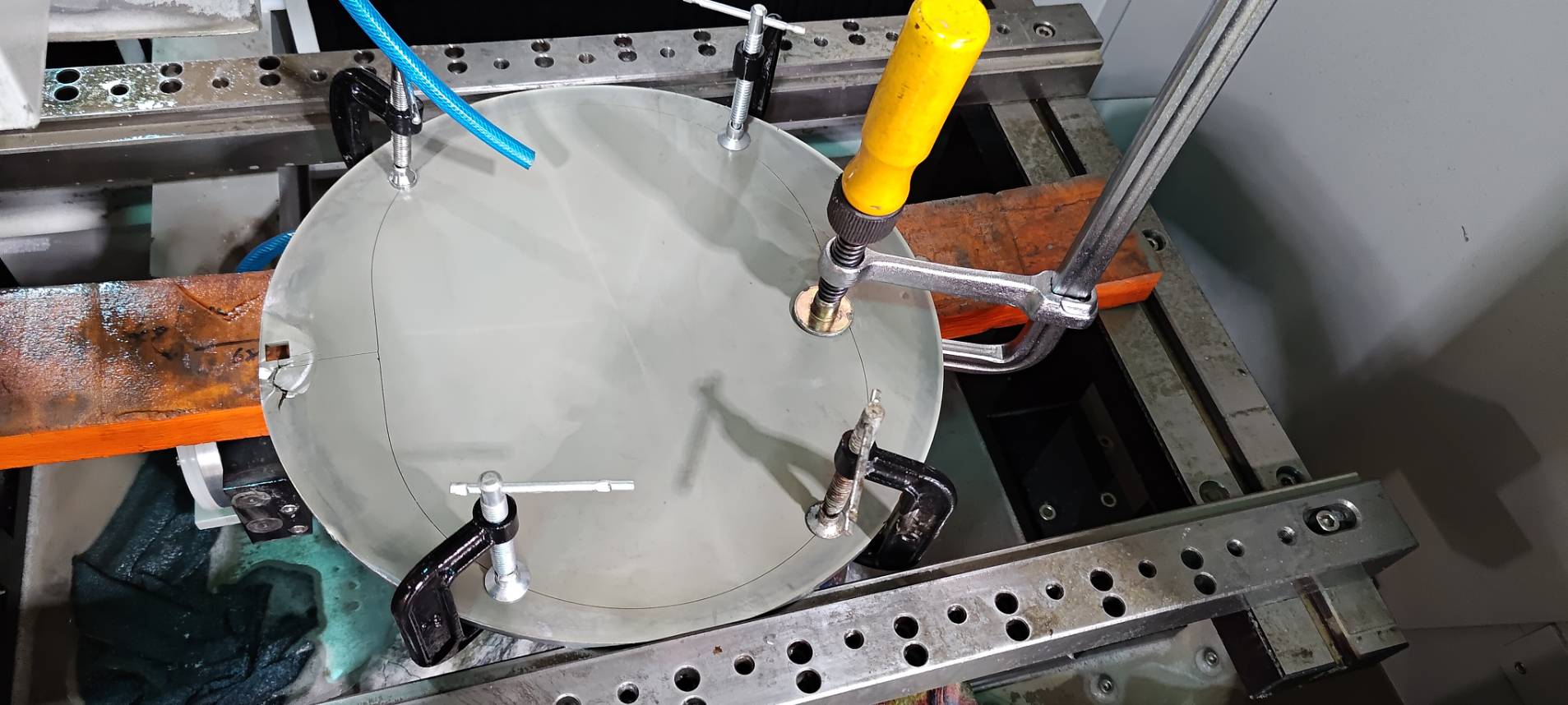

| 3. | Clampers & kits. | 1 set |

| 4. | Positioning jig. | 1 set |

| 5. | Tools & toolbox. | 1 set |

| 6. | Abrasive Wire Dia. 0.33mm | 1 roll |

| 7. | Dielectric liquid | 18 kg |

| 8. | Operation manual. | 1 set |

| 9. | Dielectric filtering Tank | 1 set |

Copyright © 2022 . Designed By J&M